WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

efficient vertical roller mills (VRMs) led to their replacement. Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding – with its finer grinding requirements – coming more recently, in the late 1990s. The main reason for

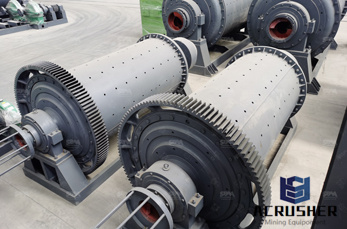

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and roller mill has many different forms, but it works basically the same.

Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014.

Main Spare Parts for Vertical Cement Raw Mill: main shaft, seals, grinding table, grinding roller, hydraulics, rods, sleeves, bearings, sluice, wear plates, liner Introduction: Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cement and ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Clinker Grinding Unit, Thermal Power Plant Capacity : 50250 t/h

Jul 21, 2017· This video is unavailable. Watch Queue Queue. Watch Queue Queue

After the material is discharged proportionately by the feeding metering equipment, it is sent to the ball mill by the belt conveyor for grinding. 7. Cement grinding Cement grinding is the last working procedure of cement manufacturing, and is also the most power consuming process.

Sep 04, 2013· Vertical Roller Mill is a new type of grinding mill based on years concentrated design and development by introducing advanced European technology. The processing capacity ( from 1 to 150 ton per ...

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

Vertical Mill applies to grind coal, coke, cement raw material, gypsum, barite, phosphorite, calcite, kaolin and other medium degree hardness solid material. series vertical mill is integrated with crushing, drying, grinding and separating. Process flow is easy. Compared with tube mill, vertical mill has many advantages.

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

Cement(Clinker) Supply vertical mill,rotary kiln,ball mill. ZJTLK Cement vertical mill is a new type vertical mill of our company,designed by cement clinker grinding process, it integrates grinding, drying and sizing. Get Price

The vertical grinding mill created by SBM Machinery is ecofriendly, that is focused on cement clinker processing for use again. SBM vertical grinding mill is particularly appropriate for top yield powder production in cement industry, coal gangue and fly ash processing (grinding station).

Portland cement clinker vertical mill, vertical roller mill has features of low cost, high capacity, easy operation; Comparable with Raymond mill for coarse powder up to 325 meshes, it can produce fine powders between 47 and 5 microns (300 to 3000 meshes)

A wide variety of cement clinker vertical mill options are available to you, There are 167 cement clinker vertical mill suppliers, mainly located in Asia. The top supplying countries are China, Russian Federation, and Algeria, which supply 98%, 1%, and 1% of cement clinker vertical mill respectively.

Cement production layout is that at the mine to built of cement clinker production line, in large cities near the cement sales market to establish a new cement grinding plant . Most of the cement admixture is the city''s industrial waste generated, new cement clinker grinding plant can greatly digest cities nearby slag, fly ash, slag and other ...

Vertical Cement Grinding Mill produced by China ZK Corp is is a new type of high efficiency, energy conservation and environmental protection of grinding equipment, widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum ...

Nov 23, 2017· Vertical roller mill: * Brand:Shuguang * Parameter:see form * Vertical roller mill is short for grinding, which is used for cement raw material, cement clinker, slag and cinder mill. It has the characteristics of simple structur...

The cement vertical roller mill is one of the most important cement equipment. It is the key grinding machine of materials being crushed. The cement grinding mill plays a vital role in cement production line and cement production process.

New Vertical Cement Grinding Mill Rates For Sale « Rock. vertical cement grinding mill design in india for sale sbmmine ... Concrete Surface Grinder | eBay. ... The grinding of cement clinker and granulated blast furnace slag in roller grinding mills vertical airswept grinding mills is a technology introduced by LOESCHEnbsp...

Filter: advanced process control air pollution control ball mill ball mill drive cement cement grinding cement production cement rotary kiln clean clinker cooling co2 emission coal grinding ecs/processexpert expert system fabri fabric fabriclean filter flsmidht fl fl maag gear fl; energy efficiency gas gear overhaul gearbox ...

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process.

grinding conditions associated with fine grinding of cement clinker and related products, enabling a high grinding efficiency and stable operation. Figure 3: H However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball