WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

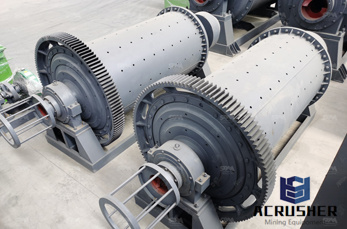

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Conical Ball Mill . Conical Ball Mill is the key equipment for fine grinding after material being crushed It is widely using for cement silicate product construction material refractory material chemical fertilizerferrous or nonferrous metel and glass ceramic which it has two types Wet type and Dry type

OSG offers square, roughting, ball nose, corner radius, tapered and double end end mills, as well as routers and burs.

The Conical Mill is now being used in all parts of the World, having substituted these latter types of ma chines in the grinding of ores and other materials. Hardinge Conical Ball Mills are used to do the work of any combination of the above machines and will pro duce the desired results, depending upon the size and type of mill used.

conical ball mill design thinkgloballysouthjersey. TECHNICAL NOTES 8 GRINDING R P King Mineral Technologies conical ball mill design,Ld is the mean length of the conical ends and is calculated as half the difference between Let VB be the volume of steel balls in the mill, VMed be the Rod and ball mills in Mular AL and Bhappu R B Editors Mineral ...

A general guide to the design style and time period for antique vintage coffee grinders, The ball bearing conical burr adjustment was a Peter Dienes invention . chat online; antique conical ball mills rearsbyschoolorg. antique conical ball mills antique burr mill cast iron MTM Crusher antique burr mill cast iron Antique coffee mills Logan ...

These tools have a tapered profile and rounded cutting edge for making smooth contours on intricate, threedimensional shapes. They''re also known as taper degree end mills. Made of solid carbide, they''re harder, stronger, and more wear resistant than highspeed steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup ...

Hardinge Conical Ball Mill Mineral Processing Metallurgy. The Conical Mill is now being used in all parts of the World, having substituted these latter types of machines in the grinding of ores and other materials. Hardinge Conical Ball Mills are used to do the work of any combination of the above machines and will produce the desired results ...

Feb 20, 2018· The taper ball nose can "easily" reach 1" but a straight 1/32 will reach maybe 1/4" if you are REALLY lucky. Personally, I use tapered ball nose cutters a LOT. I have 1/32 1/16 1/8. I pay generally about 3236 each BUT it gets better. I did buy some Chinese Ball nose cutters. They were metric, but that does not matter at all, at all.

Conical Ball found in: Amana Tool 46286K CNC Spektra Extreme Tool Life Coated SC 2D and 3D Carving Deg Tapered Angle Ball Nose x 1/8 D x 1/16 R x.. Round Balls vs. Conicals for hunting Jan 05, 2010 Round ball loads specify T/C patch material lubricated with T/C no. 13.

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. ... Some mills have a conical section. In the conical section near the discharge, fine particles preferentially move into the conical ...

potash feldspar cone ball mill machine . Potash Feldspar Grinding Mill SKDminings Ball mill for potash feldspar The ball mill designed by SKD company is an efficient tool for grinding various ores and rocks It is suitable for grinding potash feldspar and it features with simple structure easy to operate wide range of applications even final products lower maintenance and.

The Hardinge Ball Mill consists of three sections. After the usual type of trunnion bearing the mill consists of a short conical section showing a sharp drop from feed entrance to maximum mill radius. A cylindrical section of varying length then follows and toward the discharge end connects with a comparatively long and conical section sloping, at considerably less pitch than at the feed end ...

CARBIDE TAPERED END MILLS. FEATURES BENEFITS Every good machinist knows you need all the options you can get to tackle difficult engineering challenges. From varying diameters; stub, regular, long extralong lengths, to square end; corner radius ball ends options, there is a Conical Tapered Carbide end mill.

Ball Mills 911metallurgistThe only conical ball mills on the market are those made by the . Fig. 12 shows the construction of this type of mill. It consists essentially of a short cylindrical section with conical feed and discharge ends. The shell is made up of steel plates riveted or welded together.

Online Sale Conical Ball Mill For Sale. Online Sale Conical Ball Mill For Sale. Conical End Mill Suppliers, Manufacturers, Factory .We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a winwin prospect for our clientele likewise as us for Conical End Mill, The products has a good reputation with competitive price ...

6mm HRC55 2 Flutes Tungsten Steel Taper Ball Nose End Mill CNC Drill Bit Tool. Details: * brand new and high quality *Quality tungsten steel alloy taper Taper ball end mill *Tapered Ball Nose End Mill / Cone Cutters *More durable *Model: * D6 * * 75L *Material: tungsten steel *Surface processing: Coating *Flutes: 2 Flutes

Conical created and eventually patented the tapered end mill in the 1940''s. Everything about the design of this tool suggests mature engineering. With a variable lead spiral, tapered .

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

We have chromium conical ball mill,Quadro invented the original cone or conical mill in 1976 Though simple in principle the Comil was a revolutionary concept that has since evolved into a global processing standard adopted by market leaders around the world The Cone Mill is typically used for some of the following common applications Sizing wet granulated particles before

Cylindrical Ball Mills differ usually in steel drum design (Fig. ), which is lined inside by armor slabs that have dissimilar sizes and form a rough inside surface. Due to such juts, the impact force of falling balls is strengthened. The initial material is fed into the mill by a screw feeder located in a hollow trunnion; the ground product ...

Conical Ball Mill Design. The Conical Ball Mill Manufacturing Proven Experience Minerals draws from more than 100 years of mill design and manufacturing expertise and nine decades of successful Conical Mill applications Get Price And Support Online Mill (grinding) Wikipedia.

Conical ball mill design thinkgloballysouthjersey technical notes 8 grinding r p king mineral technologies conical ball mill design,ld is the mean length of the conical ends and is calculated as half the difference between let vb be the volume of steel b...