WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment; 3. Coal particles in the ground in a mill, grading, Eligible grader after the powder was collected by unqualified, Powder will be regrinding;

A wide variety of vertical coal mill options are available to you, such as ball mill, raymond mill. You can also choose from free samples. There are 1,039 vertical coal mill suppliers, mainly located in Asia. The top supplying countries are China (Mainland), Ukraine, and Turkey, which supply 99%, 1%, and 1% of vertical coal mill respectively.

2. After grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill. 3. The mixture of hot air or waste gas of cement production line are sucked into Vertical Coal Mill, under blower''s function ...

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

Power Plant Machines – Coal Mill NHI Group, the coal mills manufacturer, is the key enterprise in the industry of power plant machinery. Every year, NHI Group provides hundreds of sets of production capacity, and the performance of our coal mills has reached the .

As a professional manufacturer and supplier of vertical mill in China, CITIC HMC Co., Ltd can also provide you with various other machines, such as vertical coal mill, jaw crusher, cement production line, cement grinding plant, industrial kiln and furnace, grinding equipment, crushing equipment, environmental protection equipment, cooling equipment, drying equipment, compound fertilizer ...

Discussion on Optimization Plan of Grinding Roller of Vertical Coal Mill Optimization of the grinding roller drive system. In the drive scheme of Vertical Coal Mill, the commonly used transmission types are gear transmission, chain drive, twoway synchronous belt .

Vertical roller mill Introduction. The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, feldspar, gypsum, barite and coal etc..

LM Vertical Grinding Mill. Based on the absorption of advanced technologies of famous international corporations and 30 years'' experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding.

Nov 16, 2011· loesche Vertical Mill LM modo1231. ... Start Up Sequence of a Loesche Coal Mill Duration: 8:12. LoescheGroup 20,512 views. 8:12. Loesche Grinding Plant for Solid Fuels Duration ...

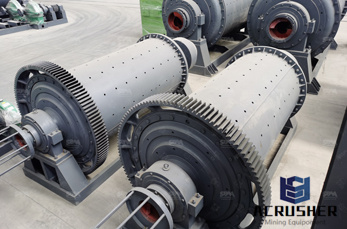

Coal mill is a machine that crushes and grinds the coal briquette into pulverized coal. It is important auxiliary equipment of pulverized coal furnace. During the coal grinding process, the coal is crushed and its superficial area increases continually.

is employed for coal grinding mills and mills in the cement and industrial minerals industry. 2, 3, 4 or even 6 grinding roller configurations for a single grinding table can be realised. The first Type LM D modular coal grinding mills were developed in 1980 .

Jun 14, 2019· Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill''s main components, how it works and some of its design features. For this video, we assume ...

Whether in cement works, steel mills or power plants, whether direct or indirect firing: Our ATEXcertified coal grinding plants have proven themselves internationally in all areas of application. We also develop customtailored concepts for closeddown ball mills in the cement industry.

Coal vertical mill Capacity: 558 t/h Applicable materials: Coal quartz feldspar calcite and etc. Coal vertical mill is a mechanical device used to pulverize coal for combustion in steam generator of fossil fuel power plant.. Enable Ginger Cannot connect to Ginger Check your internet connection or reload the browser Disable in this text field Edit Edit in Ginger Edit in Ginger ×

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a dynamic classifier produces coal fineness levels of .

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special versions are available with characteristics that meet special safety regulation or output control requirements.

CHAENG pulverized coal grinding system specifications can be divided into: vertical coal mill, vertical coal mill, vertical coal mill, its production capacity is designed to be divided into: 20t / h, 25t / h, 40t / h to meet a variety of applications on the market in the field of coalfired boilers

Description of roller mill coal grinding: roller mill coal grinding is also called raw meal vertical roller mill, and it is the core equipment applied for cement raw meal grinding. In 1971, first Phi;1m ball mill in China was produced in Great Wall Machinery, and open the door to cement equipment industry for us.

Within the power industry, vertical roller mills (VRMs) are the predominant equipment used for coal pulverisation. The essential requirements of pulverisation are grinding, heating, classification and transport of the pulverised coal from the pulveriser.

GRMC coal vertical roller mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China. It is the first choice equipment for grinding raw coal and bituminous coal. 1. The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen.

for mills PULVERIZERS CE RAYMOND Roller Mills CE Raymond Bowl Mills ... Mills are capable of grinding harder coal with higher ... in the vertical mill include GRAPHITE, TALC, COCOA, LIMESTONE, KAOLIN, PHARMACEUTICALS, and VARIOUS FOOD PRODUCTS.

Vertical Coal Mill On the basis of retaining the advantages of RP grinders, the innovative HP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders.