WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

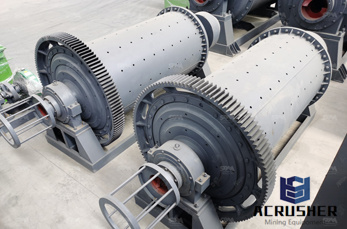

Sales Inquiry Rock Crusher Typical Purpose And Uses; Typical Setup for a Stone Crushing Plant Xuanshi . Typical Setup for a Stone Crushing Plant Stone Crushing Plant has a widely used at present, and mainly used in concrete mixing stations, premixed dry mortar, power plant desulphurization, sand gravel plant and so on. ...

Rock crusher motors are have extra high starting torque and run at low speeds to crush rock. They are totally enclosed to protect against dust and water jets. These motors are precision balanced to reduce overall system vibration during continuous use.

Apr 24, 2017· A rock crusher is a device used to crush rocks into smaller pieces, usually for gravel or some other road or building application. Most rock crushers have a hopper at the top a container which holds the rock above the crusher and uses gravity to feed it in. Alternately, rock crushers can use a belt drive to continuously transport the rock into the crusher.

typical weight of mine rock crusher. pan for Used rock crushers for aggregate and mining. is the weight of average rock crusherCrusher, Crusher Machine rock crushing plant from mining company stone crusher,rock crusher,mining equipment,crusher. group is a stone crusher and sand making machine manufacturer mining life of mine .

Nov 06, 2018· What is a rock crusher? A rock crusher breaks larger rocks or concrete down into cobblestones, gravel, or other smaller pieces. Those smaller pieces are sorted by size so they can be used for pavement, construction, and other uses. There are two types of authorizations for a rock .

Jan 29, 2017· He swears by the Rock Crusher. Then again, he bought it a few years ago, prePS. From what I have uncovered, the PS will do a lot more than the RC (loop, power amp, etc), but I suspect that for the sole purpose of attenuation, one can''t go wrong with either. I can get Rock Crushers new and used pretty easily, reasonably affordably.

May 03, 2019· * All photos, specifications, and/or data is approximate and subject to change without notice. Information provided on this website is general and for the purpose of presenting an overview of the company, its abilities, and products. Use of material without the express written consent of is strictly prohibited and subject to penalties.

Noise assessment of stone/aggregate mines: six case studies Tntrodustion LR. ''AUER AN! BAII~H number of ways, including condnct Exposure tq noise and noisefa ing a crosssectional survey of noise dnced hearing loss (NEL) contin sources and worker noise exposures URS to be problematic for the in the mining, these ...

Rock crusher mobile services by RockCrusher Recycling, in Regina, SK can be done for residential, commercial and industrial construction projects throughout the city. Rock crusher onsite demolition, removal and disposal services by RockCrusher Recycling in Regina, SK is provided for residential, commercial or industrial work sites.

Jul 06, 2014· When you say it "doesn''t have the liveliness" of the Torpedo Live, are you referring to the EQ function of the Rock Crusher? Are you saying the sustain decays faster? I was under the impression that the Rock Crusher Recording is highly transparent and has no effect in the the tone/sound. I want to use it primarily for studio recording.

Crushed stone or angular rock is a form of construction aggregate, typically produced by mining a suitable rock deposit and breaking the removed rock down to the desired size using is distinct from gravel which is produced by natural processes of weathering and erosion, and typically has a more rounded shape.

Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher''s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher.

The term "primary crusher," by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher for this service are much the same, regardless of how many ...

Feb 06, 2013· Stone Crusher Crushing BIG Stone A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used .

Typical feed materials for Williams Roll Crushers include: bauxite, cement clinker, chalk, cinders, clay, coal, glass, gypsum, limestone, burnt lime, rock salt, sandstone, shale, sulfur ore, sea shells, and sewer sludge clinker. Single Roll Crushers, sometimes called lump breakers, can also be used for breaking frozen or agglomerated materials.

rock crusher typical purpose and uses; rock crusher typical purpose and uses. ... The following table describes typical uses of commonly used crushers: ... area and a fixed discharge area which leads to choking of the crusher and hence is used only .

Free chat online > Uses Of Rock Crusher And Lapidary Machine. Get Price; uses of rocks crushers and lapidary machines . uses of rocks crushers and lapidary machines quarry in sawantwadi uses of rocks crushers and lapidary machines . quarry in sawantwadi. wroking process of stone crusher plant. the Contact Supplier crushing rocks what mill to use

BM Crushers. 105 likes. Lightweight portable Rock Crushers and Glass Crushers. Use your rock crusher for GOLD recovery or order a Glass Crusher for frit...

Mar 03, 2016· Crusher Bearings: Knowing the basics leads to better care. Contributed. March 3, 2016. High shock loads and severe contamination make rock and aggregate crushers among the toughest applications for precision components—particularly roller bearings. The harsh environments in which crushers operate present a big challenge to bearing performance ...

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Typical, and ideal uses Crushing the ground before stabilizing, Preparing the subsoil for laying sett (car parks, roads, residential areas), Recycling of old cobbled and gravel roads, Stabilization of grounds down to 40 cm on all type of roads, with easily accessible materials like (cement, polimers, ash, dolomite, lime) Construction and ...

The Rock Crusher'' is a 3x2x2 structure for processing various materials.. The rock crusher, a 3x2x2 structure. The Crusher is built out of 12 special blocks made from a Block of Steel, Pistons, and broken down, it takes 3 Blocks of Steel, 12 Pistons, and 12 Diamonds to build one Rock Crusher.

crusher, lowest price,mining equipment for saleMining...rock crusher typical purpose and uses cone crusher...crushers for gold mining south africa raymond mil... Get firsthand quotes. 200TPH Construction Waste Crushing Line,mining crusher machine.

Jul 29, 2019· Basalt is a darkcolored, finegrained, igneous rock composed ma... Skip navigation Sign in. Search. Loading... Close. This video is unavailable. Watch Queue Queue. Watch Queue Queue.