WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Advanced Machining Processes (electrical, chemical, thermal, hydrodynamic, lasers) ... medium Process Mechanical Rigid Chemical Liquid Granular Electrical and Chemical Liquid Liquid/ Gaseous ... • In slab, or peripheral, milling the axis of cutter rotation .

milling (a nano material process) on the microstructure and mechanical properties of a(AlSiFeCu) alloy" submitted by Sri Kaushal Kishore Singh and Sri Sudipto Bhattacharjee in partial fulfillment of the requirements for the award of Bachelor of Technology Degree in .

Zirconium Machining Forming Operations Zirconium Machining Forming Operations INTRODUCTION Zirconium is a hard, shiny, grayish white metal. With its superior corrosion resistance capabilities, it has increasingly become the material of choice in the fabrication of .

Milling is a process of removing metal by feeding the work against a rotating multipoint cutter. The machine tool intended for this purpose is known as milling is found in shops where tools and cutters are manufactured. The surface obtained by this machine tool is superior in quality and more accurate and precise.

Milling is an interrupted cutting operation Cutting tool called a milling cutter, cutting edges called "teeth" Machine tool called a milling machine ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" ...

MECHANICAL WORKSHOP Presentation on By: Hafiz Muhammad Rizwan . PPE Suitable Personal Protective Equipment ... • Horizontal milling machine handles operation normally performed by other tools . TYPES OF MILLING AND ITS PARTS . VERITY OF OPERATION Face milling.

mechanical milling operation pdf mechanical milling operation pdf Milling Operations Mechanical Engineering Blog Milling Machine Milling is the process of removing metal by feeding the work past against a rotating multipoint cutter. MACHINING OPERATIONS .

A Milling fixture is a work holding device which is firmly clamped to the table of the milling machine. It holds the work piece in correct position as the table movement carries it past the cutter or cutters.

End Milling is the milling of a flat surface with the axis of the cutter perpendicular to the machining surface as shown in figure 17. Figure 17. End Milling Gang Milling Gang milling is a horizontal milling operation that utilises three or more milling cutters grouped together for the milling of a complex surface in one pass. As ...

pulping process is shown in figure 21. Mechanical, semichemical, and sulfite pulp mills differ in detail, particularly in wood preparation, fiber separation, and bleaching, but many of the downstream refining, bleaching, and papermaking processes are similar. In addition to the primary steps in pulp and paper manufacture, each mill has ...

Dec 09, 2016· In this article you will able to learn about what is milling machine operation, parts and types. Milling machine is the backbone of the manufacturing industries. Almost it is capable of doing any milling operation whether it is gear milling, thread milling, angular milling etc. Here we will discuss about definition, main parts, types and ...

Download PDF Download. Share. Export. Advanced ... years in the synthesis of equilibrium and metastable alloy phases by a simple and inexpensive processing technique — mechanical alloying/milling of metal powders. The outline of the review will be as follows. ... has summarized the historic origins of the process and the background work that ...

INSTRUCTIONS HOW TO USE A MILLING MACHINE Milling is the process of machining flat, curved, or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges. The usual Mill consists basically of a motor driven spindle, which mounts and revolves the milling

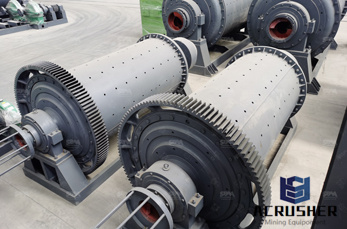

Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing ... For systems with multiple components, ball milling has been shown to be effective in ... it is suitable for both batch and continuous operation, similarly it is suitable for open as ....

Mechanical Milling Operation Pdf. You are here: Home / mechanical milling operation pdf modeling of milling process to predict . modeling of milling process to predict surface roughness using artificial intelligent method mohammad rizal bin abdul lani thesis submitted in .

milling machines, sawing machines, drilling machines, broaching machines, grinding machines, gear ... Department of Mechanical Engineering. (effectiveness of each midterm is 25%) One homework (effectiveness is about 10%) ... the nature of machining operation used for a particular material.

PDF | Mechanical processing can be used to obtain metastable crystalline phases,, phases that can only be reached at equilibrium using high temperatures and/or pressures, or even amorphous ...

In particular, mechanical attributed contamination by the milling tools (Fe or WC) as well as ambient gas (trace impurities such as O 2, N 2 in rare gases) can be problems for highenergy ball milling. However, using optimized milling speed and milling time may effectively reduce the contamination.

the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and .

Feed Mill Design By Fred J. Fairchild, P. E. Department of Grain Science and Industry Kansas State University . Determine Needs Determine Purpose ... The process flow of the mill must be defined and drawn before any physical layout of the mill is started. Provision for future equipment and

processes include turning, milling, drilling, grinding etc. mechanical operations. Back in the 1940s the needs of the defense industry, aviation and space industry, electronics and other industries necessitated ... 1. chemical milling, 2. chemical ... Manufacturing Processes and Materials: Exercises

3. Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End ...

2. Mechanical Milling: Equipment and Process Variables The milling of materials has been a major component of the mineral, ceramic processing, and powder metallurgy industries. The objectives of mechanical milling include particle size reduction, mixing or blending, particle shape changes and synthesis of nanocomposite.

THE DRILLING PROCESS. After a workpiece is laid out and properly mounted, the drilling process can begin. The drilling process, or complete operation, involves selecting the proper twist drill or cutter for the job, properly installing the drill into the machine spindle, setting the speed and feed, starting the hole on center, and drilling the hole to specifications within the prescribed ...